3M™ Clean-Trace™

Simply, ensuring cleanliness.

90 of the top 100 food brands trust 3M Clean-Trace to help deliver safe, quality food to people worldwide. In 2020, the COVID pandemic increased the demand for Clean-Trace as a part of cleaning protocols in other industries and drove the 3M food safety team to provide an improved cloud-based experience.

Peanut butter recall

In 2008, this mother, dog-lover, and cancer survivor Shirley Almer, of Brainerd, Minnesota, sat down for a snack of peanut butter toast that her daughter made. Days later, she became ill with abdominal pain, nausea, and a fever. Her son, Jeff, arrived at her bedside just in time to say goodbye. It was only days before Christmas when she died. Her family wouldn’t learn the cause of her illness until after she was buried. It was salmonella from the peanut butter she ate1.

Little did her family know, at the time, that this was to become one of the nation’s most significant foodborne illness outbreaks in history. It sickened over 700 people in 46 states, killed 9, and involved more than 360 companies, including Kellogg and Sara Lee2. More than 3,900 products were affected, equaling an estimated 31 million pounds of recalled peanut butter and peanut butter paste products3. It cost the U.S. peanut industry roughly $1 billion by weakening pricing and limiting sales4. It also effectively bankrupted the Peanut Corporation of America, the company responsible, and sent its CEO to prison for 28 years on charges of fraud, obstruction of justice, and selling adulterated food5,1.

The Food Safety Modernization Act (also known as FSMA), signed into law by President Obama in 2011, was enacted mainly in response to this outbreak1. FSMA shifted the focus to preventing outbreaks rather than just reacting to them. The law requires that companies implement best practices to avoid hazards introduced as part of the manufacturing or packaging process.

600 million people

are affected, globally, by foodborne illness or food poisoning every year. Of these 600 million people there are about 420,000 deaths, and roughly $110 billion lost in productivity and medical expenses6.

Environmental monitoring and Clean-Trace

Today, international standards require many food facilities to implement environmental monitoring as part of their overall food safety plan. Adenosine triphosphate (ATP), an enzyme found in organic matter, is the indicator that defines clean vs. dirty in an environmental monitoring program. 3M™ Clean-Trace™ tracks the quantity of ATP present on contact surfaces to help manufacturing plants assess their cleanliness practices and prevent contamination.

The problems

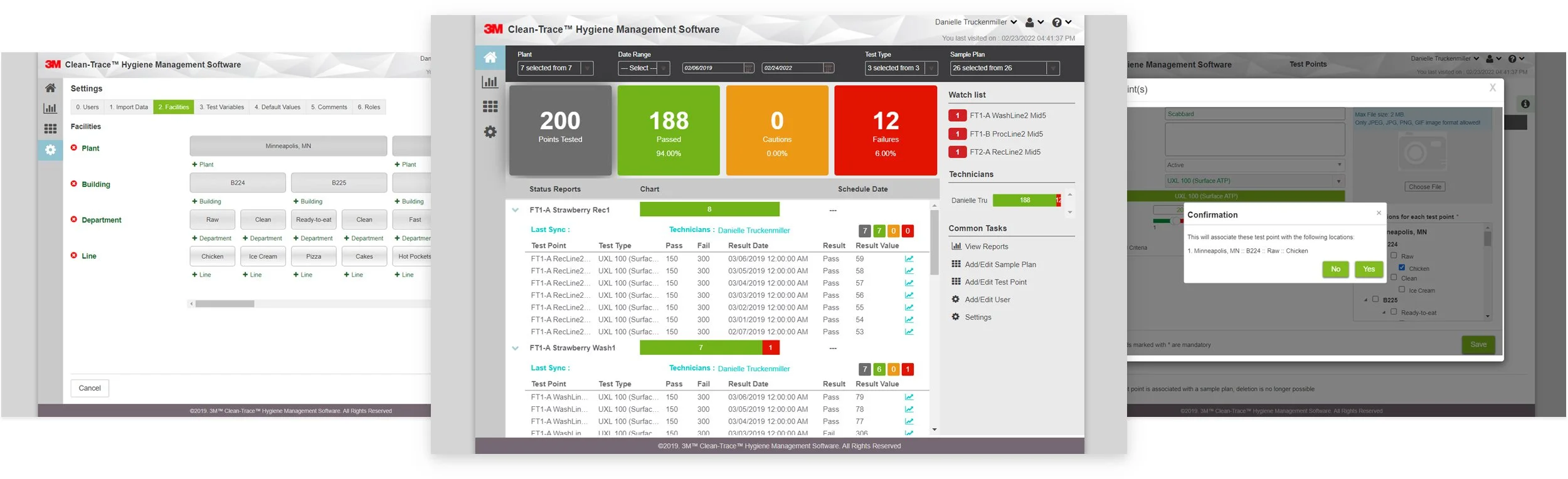

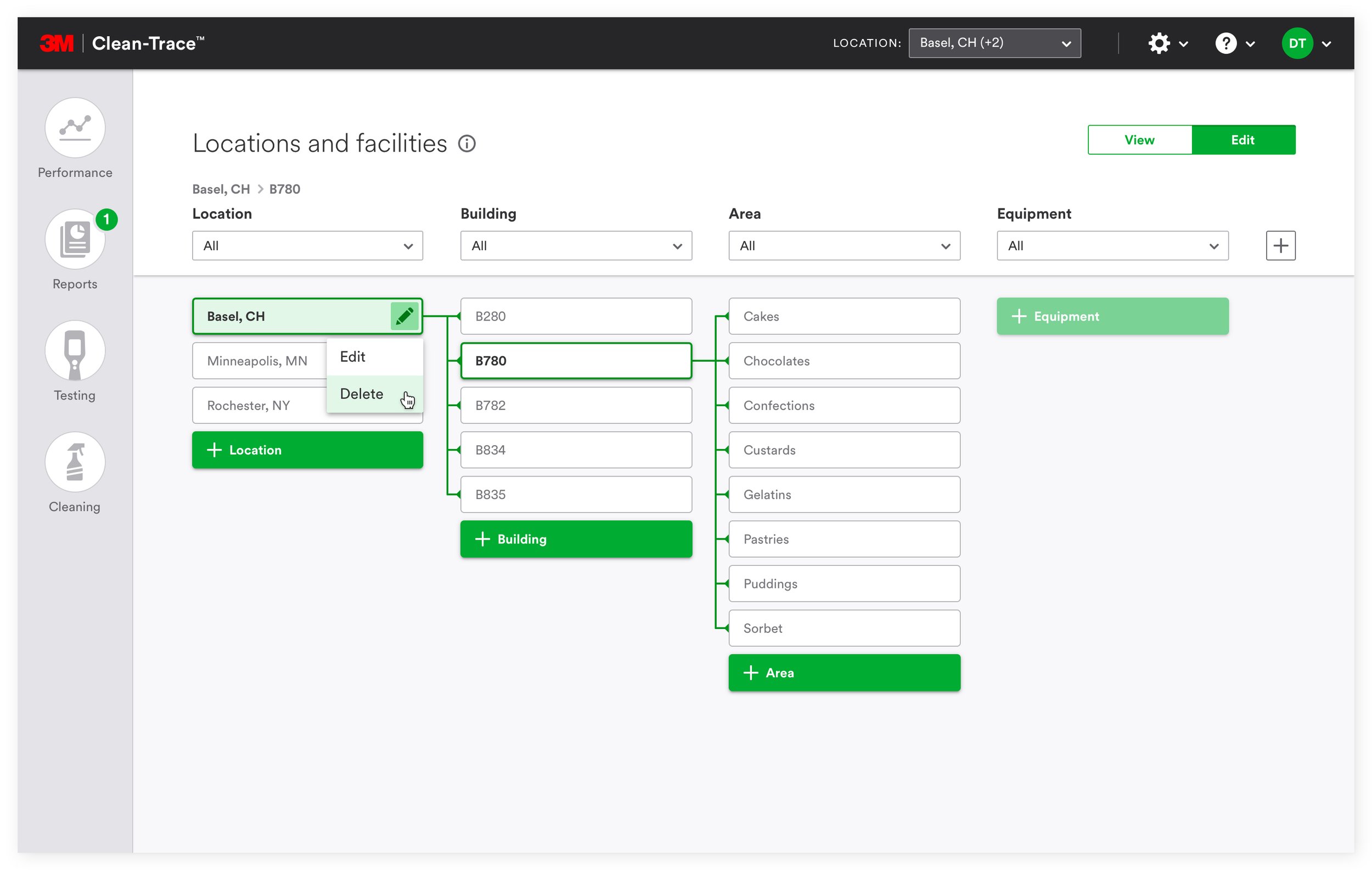

The Clean-Trace system consists of swabs (to collect samples), a luminometer (to read the swabs), and a web app, which manages the testing process and tracks readings over time. I identified a laundry list of problems through a heuristic analysis of the web app. Below are some of the most notable:

Rickety foundation

The app was supposed to support multi-location organizations, but it didn’t. Instead, the system’s design was too flexible; it allowed users to put locations anywhere in their organization hierarchy or not at all.

Confusing navigation

Illogical taxonomies and ambiguous icons amounted to navigation so confusing that “Common tasks” were implemented. Unfortunately, this didn’t solve the underlying problem; it added a navigational element that changed from page to page.

Dialog inception

Across the experience, unnecessary confirmations followed non-destructive actions within overlayed windows. As a result, users would often see a dialog within a dialog.

Obscure language

Grammar issues, vague text labels, and lengthy explanations riddled many pages. In addition, food industry vocabulary such as “Plants,” “MSS,” and “CAPA” was confusing to people in other industries.

Non-responsive design

The static application design resulted in poor real estate utilization on large monitors and horizontal scrolling on mobile devices.

Unreadable data

Sample plan and test point names are often similar and decipherable only by the end of the string. Fixed column widths made for unreadable data if the names were truncated too soon.

How might we make the Clean-Trace web application more functional, scalable, and intuitive for process leaders and testing managers?

Research

Discovery research was conducted through remote in-depth interviews because of the pandemic. Before the lockdown, I was fortunate enough to have participated in three site visits to the Coors Brewery and Red Bird Farms in Colorado and Atrium Health in South Carolina, which uses Clean-Trace in endoscope reprocessing. I talked to test operators, process leaders, and testing managers from various companies worldwide to create personas and a user journey map. The research highlighted the need for an easy-to-use testing management application that enables continuous improvement and the knowledge to make effective decisions concerning resources. There were many insights; here are a few notable:

1. Very few use reports

Only 13% of the current Clean-Trace customers I talked to use Clean-Trace reports. The majority export their data and create reports using Excel. Why? Because they need more control and customization.

2. Broken features and bugs

The application didn’t support data separation for multi-site organizations as intended. In addition, the audit log wasn’t tracking all activity across results management, and ‘Data import’ was full of bugs.

3. Frustrating filters

Page-level filters were not consistently filtering all data on results pages. Rolling date range filters didn’t reflect the way customers wanted to see their results, so they continually had to define custom date ranges.

4. Editing woes

Auditors want processors to make continuous improvements and lower pass thresholds over time. Unfortunately, the app didn’t have a way to do this outside of sample plans, so many had to edit test points one by one.

Data modeling

Our design process began with various IA activities, including a workshop with stakeholders to define the actors, actions, and assets within the Clean-Trace ecosystem. From there, we began object-oriented atomic modeling, which allowed us to construct a modular system with a solid foundation of reusable and extensible parts that interoperate efficiently.

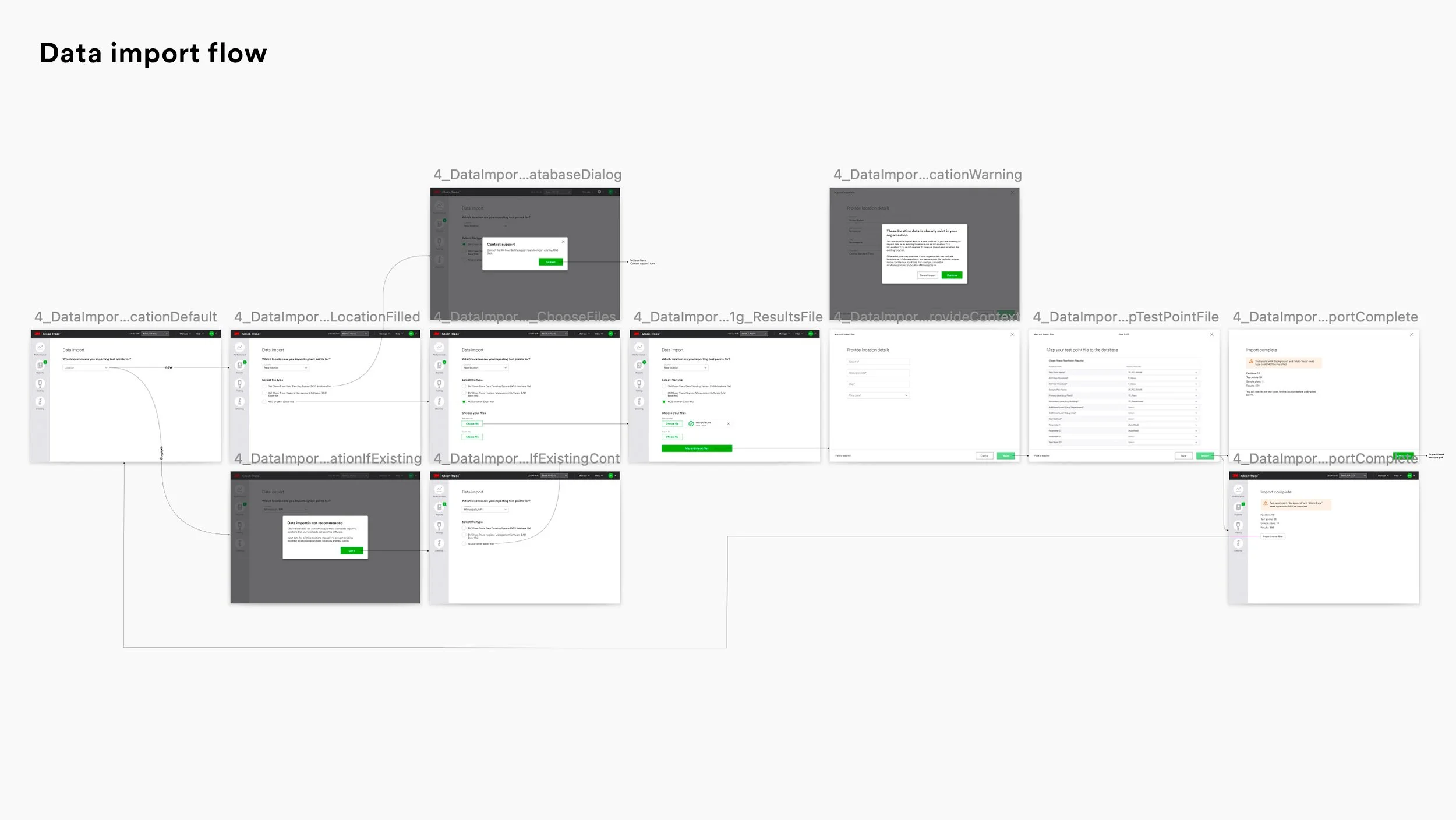

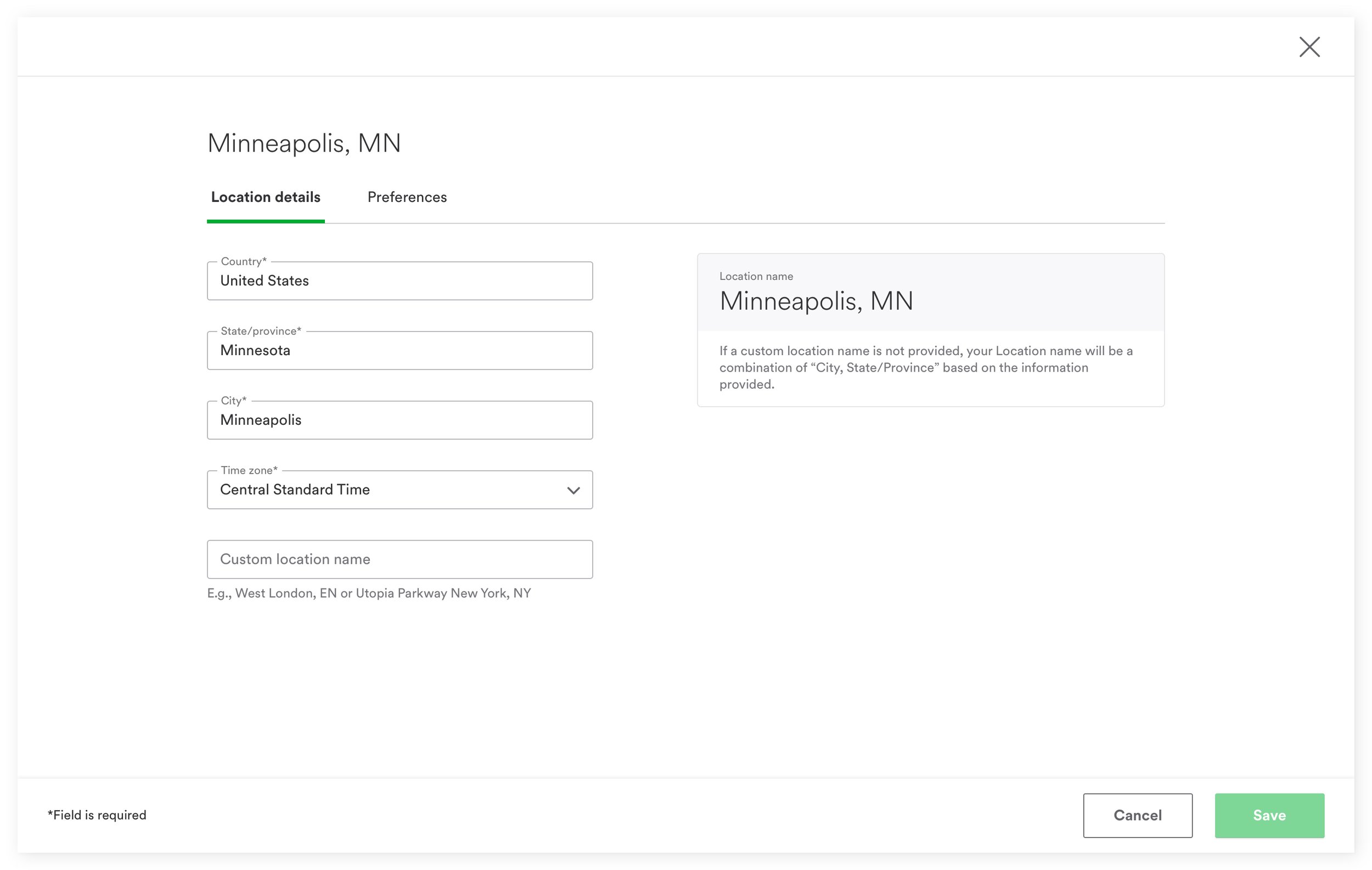

Iterations and flows

My work on Clean-Trace spanned four releases for the on-premise app, two product launches (for the Cloud and the Linux luminometer app), and 2½ years. I worked on countless user flows and iterated through many designs for hundreds of user stories. Here’s a small sample of that work:

User testing

Usability tests comparing the old and new architecture revealed a 30% improvement in people being able to find and complete tasks over the previous design. Logically organized content and icons paired with text labels were simple changes that helped overcome ambiguity.

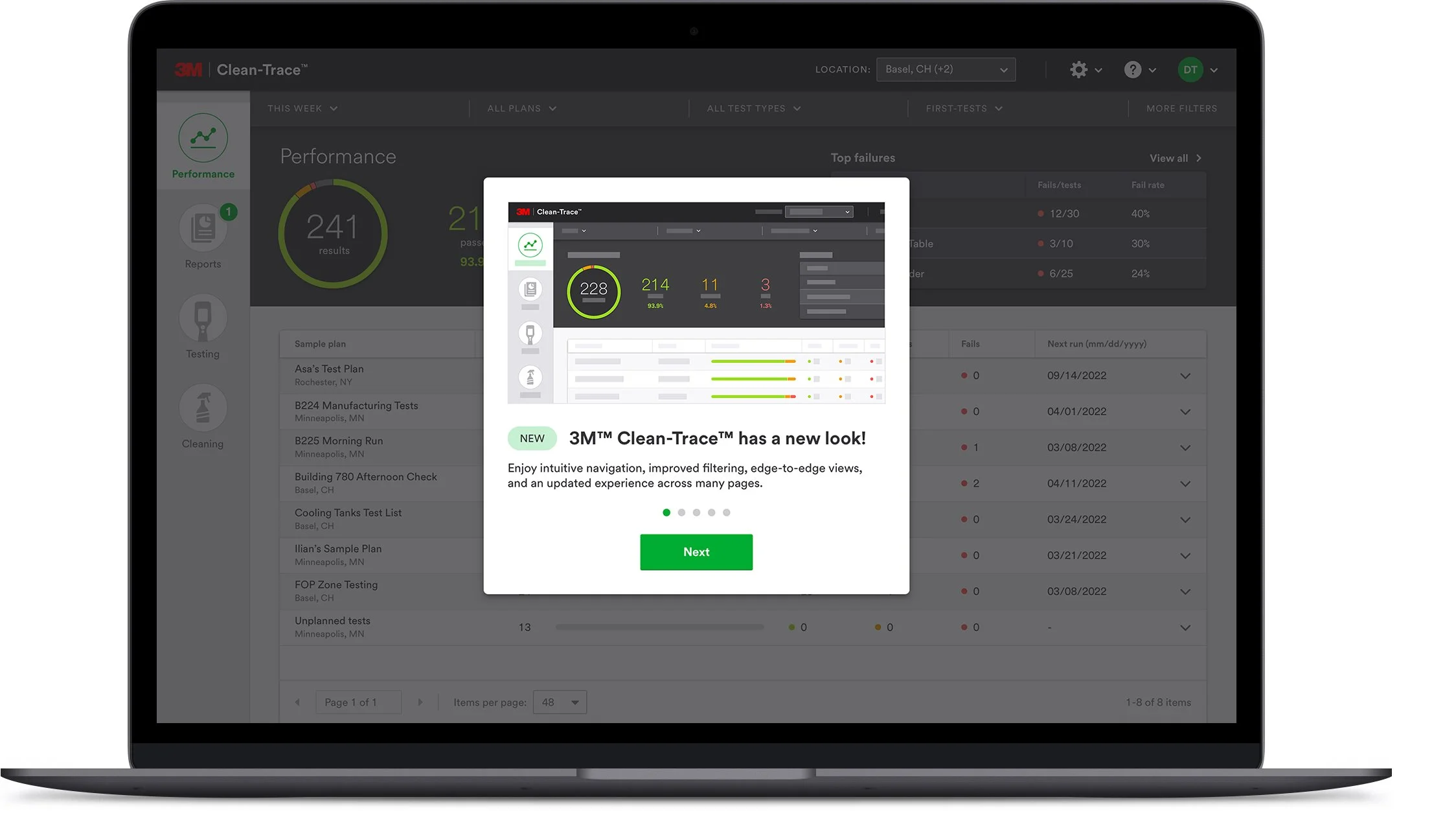

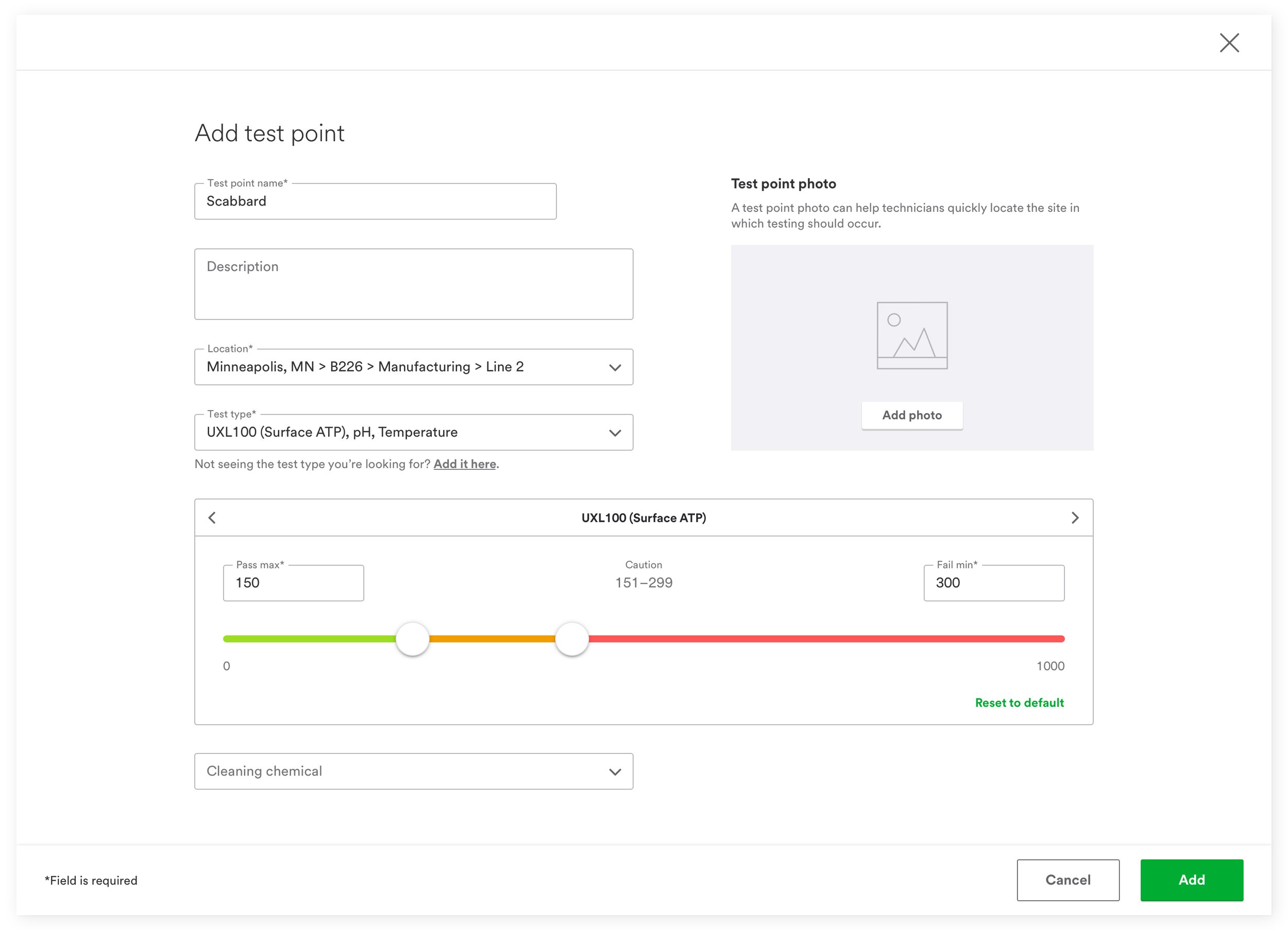

Final designs

The high-fidelity visual designs utilize primitives and components from the 3M Nucleus Design System. The cloud application will launch globally following a small-scale beta release in July 2022. The on-premise Clean-Trace software offering implemented the same designs and launched its latest release globally in April 2022.

This test point details page was one of many new features introduced to existing Clean-Trace customers. It allows users to dive deeper into a test point’s history by clicking on an individual result from the Performance or Reports page.

The initial feedback has been overwhelmingly positive with many customers, sales reps, and customer support team members commenting on how much they love the usability enhancements and the new look and feel.

Sources

Basu, Moni. “Peanut butter killed his mom; now son watches company brass stand trial.” CNN. 13 Aug. 2014.

“Multistate Outbreak of Salmonella Typhimurium Infections Linked to Peanut Butter, 2008-2009 (FINAL UPDATE).” US Center for Disease Control. 11 May. 2019.

“31 Million Pounds of Peanut Products Recalled in Salmonella Outbreak.” U.S. Food and Drug Administration. 14 Jan. 2015.

“Recall costs peanut industry $1 billion.” Reuters. 11 Mar. 2009.

Zhang, Jane. “Peanut Corp. Files for Bankruptcy.” The Wall Street Journal. 14 Feb. 2009.

Foodborne Disease Burden Epidemiology Reference Group. “WHO estimates of the global burden of foodborne diseases.” World Health Organization. Dec. 2015.